Home » Improvement » Scientific Method

SCIENTIFIC METHOD

Rapid Problem Solving

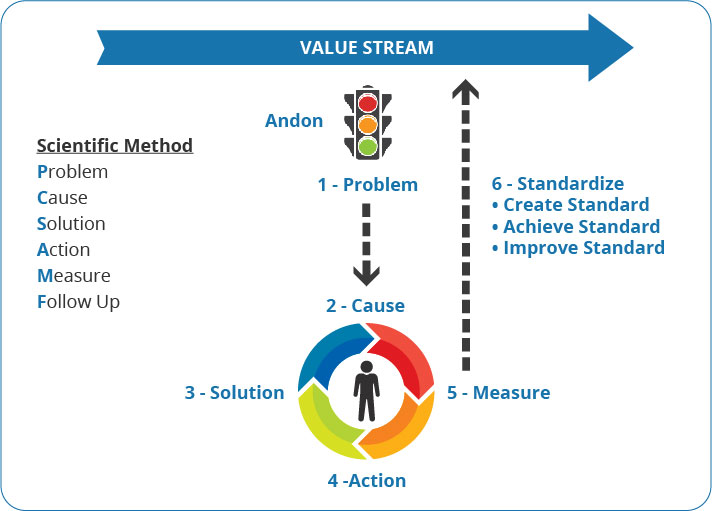

The scientific method is one of the soundest approaches to solving problems to root. We connect Andon signals (visual indicators that a problem is emerging) to the value stream at critical points, thus creating simple binary signals that alert the team when there is a problem. The team attacks the problem close in space and time to it’s occurrence. The potential causes of the problem are assessed, a solution hypothesized, actions (tests) executed and results measured. We often cycle through the Cause-Solution-Action-Measure process multiple times until we have the problem solved.

Once the problem is solved, we standardized the process so we can measure against those standards in real time. This standardization process can be any combination of creating standards where none previously existed, eliminating waste to achieve an existing standard or improving an existing standard.

Methodology Confusion?

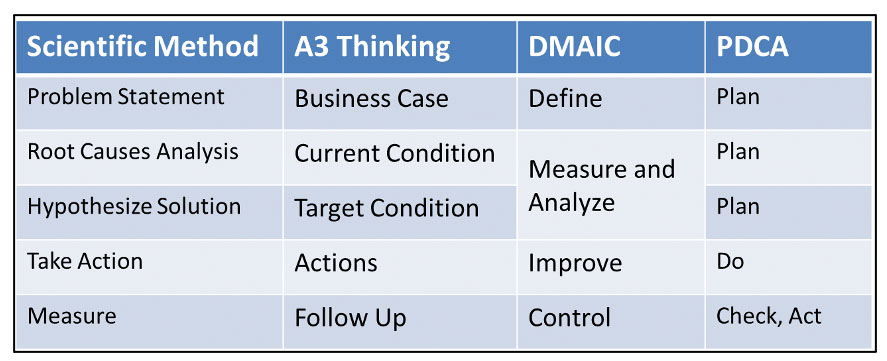

There are a number of problem solving approaches that are used. This sometimes causes confusion. At their core, these methods all connect back to the Scientific Method pioneered by Aristotle in ancient Greece. While all these processes are good, LFS prefers Toyota’s A3 approach because it is more visual, easily understood and facilitates communication. The table shows the different steps for each method.

A3 Thinking

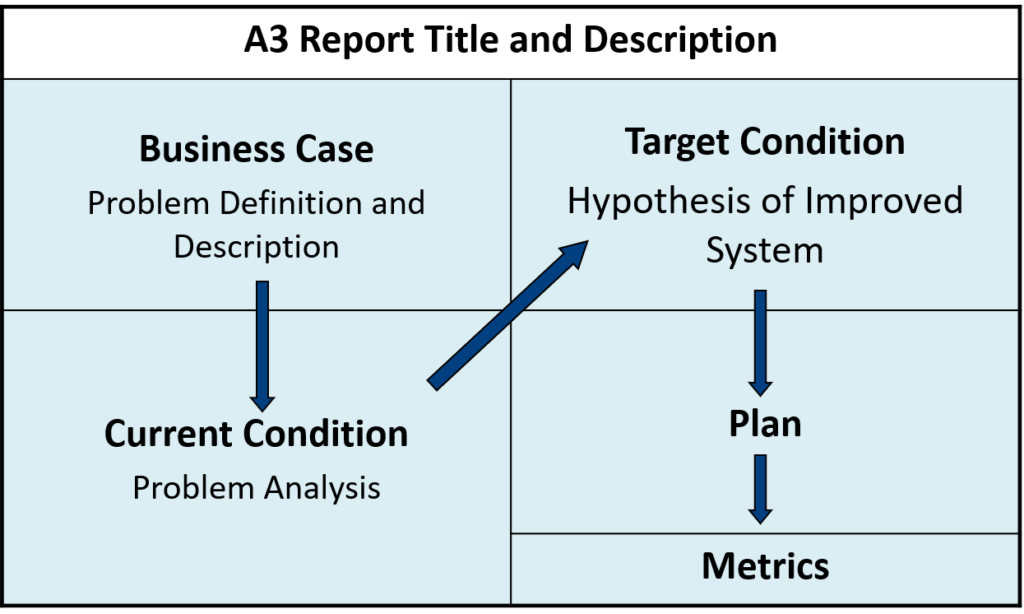

Toyota invented the A3 problem solving method. An A3 is the metric equivalent of an 11″ x 17″ piece of paper. It is the most popular paper size to construct an A3, however, any size paper or even multiple pages are acceptable. The thinking process is more important than the document size.

They say a picture is worth a thousand words. Hence, it is encouraged to draw as much as possible when developing an A3. It follows the Scientific Method, starting with the problem description in the top left quadrant, the problem analysis in the lower left, the target design in the upper right and the plan with operational metrics at the bottom right.

DMAIC

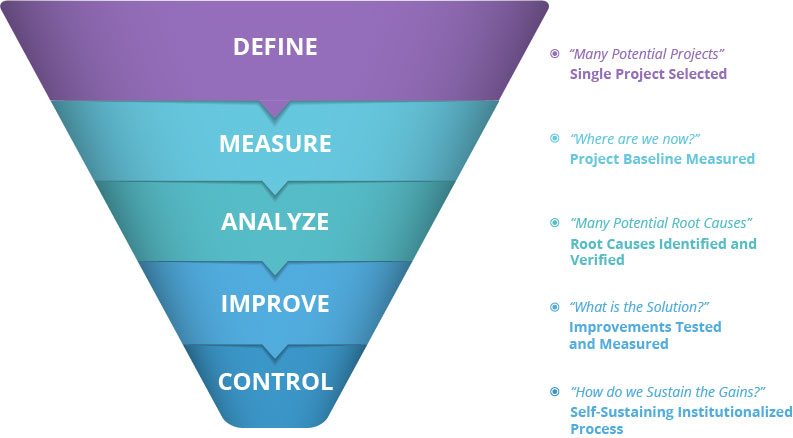

DMAIC (Define, Measure, Analyze, Improve, Control) is a methodology that came out of the Six Sigma initiative pioneered by Bill Smith while working at Motorola in the mid 1980’s. It is a data intensive approach that is used to improve processes. It was adapted by Allied Signal and ultimately brought into business prominence when Jack Welch, the former CEO of General Electric, made it central to his business strategy starting in the mid 1990’s.

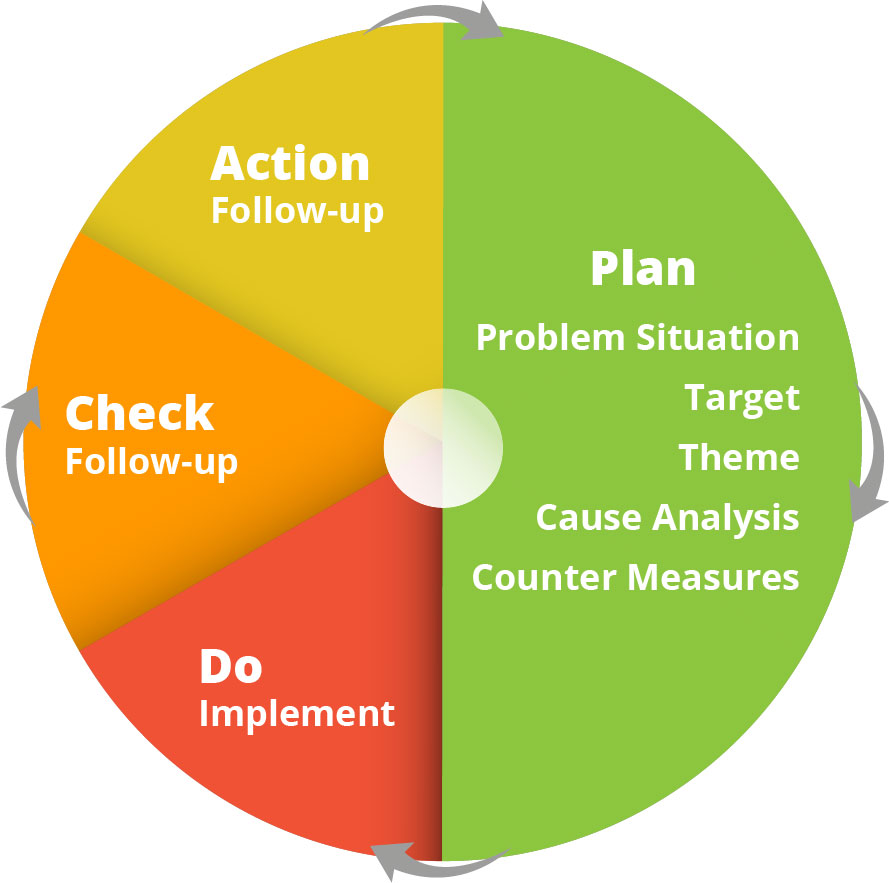

Plan Do Check Act (PDCA)

PDCA is a methodology that was created by Walter A. Sewhart and advanced by W. Edward Deming in the 1950’s. The cycle repeats to test new ideas or improve existing solutions.